HOW IS ZERO WASTE CONCEPTS APPLICABLE IN THE TEXTILE INDUSTRY?

The textile manufacturing sector is magnanimous and highly productive. This results in the superfluous amount of wastage without proper management for disposal. They mostly end up in landfills which are aggravating the problem and needs to be taken care of by introducing sustainable actions such as upcycling, recycling and zero-waste concepts.

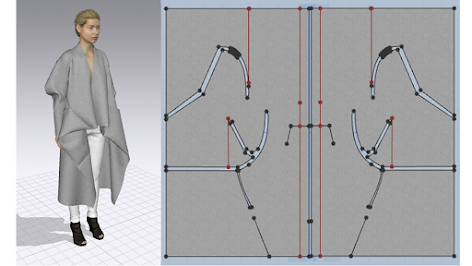

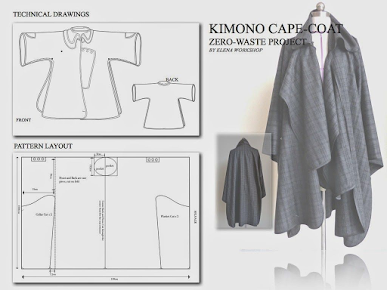

Zero waste design is a concept to design and manufacture a garment in an eco-friendly way. It is a strenuous work undertaken by designers and patternmakers to create aesthetically pleasing as well as functional apparels. Zero waste technique is a whole new alteration in the age-old pattern making technique. This technique has been used traditionally for making garments like Kimonos, Sarees and other cultural costumes. These traditional apparels uses the whole width of a fabric, thus applying the zero waste concept. Conventionally, garment manufacturing units wasted twenty percent of the fabric by scraps and the unused spaces created for pattern pieces. Currently, new-age zero waste techniques include draping, pattern cutting and knitting.

A plethora of designers have delved into the creativity of creating garments with negligible or no waste such as Holly McQuillan, Mark Liu, Zandra Rhodes, Tara St James, Julian Roberts and several others.

The pattern cutting of garments is performed in such a way, so as to create less or no waste. Creating a pattern for a garment design with zero waste requires using the width of the fabric, calculating the length, and gradually arranging the pieces aesthetically to create apparel. This technique is called the jigsaw puzzle technique. As zero waste designing is about reducing wastage, the designing and sourcing process are done simultaneously. An understanding of textile and design dimensions before working is necessary. Complicated geometries are used in the process for creating a zero waste design.

A weaving technique using a computer attached loom that helps to measure garment portions is called direct panel on Loom where the fabric pieces are hand sewn. No fabric is wasted in the process and the process is believed to minimize yarn, dyes and chemicals wastage. It is even eco-friendly as it can save almost eighty per cent of water as compared to other garment manufacturing methods used commercially.

It’s high time that the concept of zero waste patterns and designs on garment manufacturing needs to advance from high-fashion and singular design studios to mass markets in order to change the techniques how textiles are being utilized for the benefits of the sustainable way of life.

Comments

Post a Comment